|

An interesting aspect as to the

differences in the cutting methods used by the marquetarians in

the UK and those marquetarians on the "other side of the pond"

in the USA has been brought to light recently from within the

friendly environs of our Redbridge Marquetry Group.

The cause of this interesting debate and the ensuing

observations was due to the introduction to our group of a

review copy of Silas Kopf's excellent "The

Master Techniques of Marquetry" DVD. This DVD, (which

was produced in the USA) has been circulating among the members

of the Redbridge Marquetry Group recently and it has inevitably

brought to our attention the subject of the differences in

thickness between the USA sourced veneers and the veneers we use

here in the UK.

This perceived difference is that the USA veneers are twice the

thickness of the UK veneers (1/32 or 1/28th of an inch USA -

1/64th of an inch UK). That difference in the thickness of the

veneer stocks obviously obliges us both to use different cutting

methods due, primarily, to the added difficulty of attempting to

"blade" cut veneers at 1/28th of an inch thick that are

stinkers to cut when they are only 1/64th thick!,

I'm sure you'll appreciate the problems involved.

|

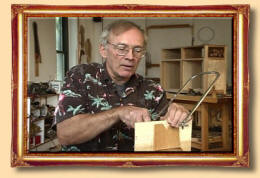

Silas uses a

"frame" saw with a foot operated

clamp system to hold the work in place

|

To illustrate those different cutting methods we are

including several clips taken directly from Silas's DVD

along with some photos of our RMG members hard at work with

their 1/64th inch thick veneers and using their trusty

scalpel blades!

In this first "clip" you can see Silas using a standard

"frame" style of saw and blade. It's actually much the same

type of tool as you will see our Alf Murtell using in his

piercing saw tutorial.

As Silas is a furniture maker he

generally uses packs of veneers, (often up to ten veneers in the

pack) in order to ensure consistency of design when multiple

marquetry inserts depicting the same design are required for a

piece of furniture.

A very important tool that's being used

by Silas in this photo is a foot operated clamp, of which you

can see a detail below.

|

|

Silas operates the clamping system by opening and closing

the clamp by just pulling the foot bar towards or away from

him.

This method leaves both hands free to

use the frame saw without restriction and to manipulate the

veneer pack as required.

The clamp system Silas is using is

obviously a large piece of equipment and would necessitate a

decently sized work shop. If you are limited with your space,

you could use the arrangements that you will see our Alf using

in his piercing saw tutorials.

|

|

This

is a parallel cutting saw arrangement that

will cut at 90 degrees to the veneer

pack |

The saw you see Silas using in this photo runs on an

arrangement of "slider" bars that ensure that the saw blade

will cut the veneer pack (of perhaps ten veneers or more) at

an exact 90 degrees to the face of the pack.

This will ensure consistency of the cut, right through from

the veneer at the front of the pack, on to the veneer at the

rear of the pack.

When the cut pieces are assembled in the

projected design there will be a uniformity achieved with this

cutting method that would not really be possible with blade

cutting.

So, for a repetitive pattern or design

needed for furniture decoration, this cutting arrangement could

not be bettered (unless you are using a laser cutter of course!)

|

|

As you will see in the picture on the right, the standard method

of veneer cutting in the UK is to use the blade or scalpel

method.

This style of cutting works well enough with our 1/64th of an

inch thick veneers, but with the USA veneers at 1/28th & 1/32nd

of an inch thickness, you will find that the blade would be

difficult to control properly.

The thicker veneers will "catch" the blade of your scalpel so

much that you will find yourself yearning for the ease that saw

cutting would promise you.

|

|

|

This photo shows a picture being cut with a scalpel.

A steel rule is being used for achieving

a clean straight cut across the border mitre.

Because 1/64th inch thick veneers are

used, a certain amount of spontaneity is available to the

marquetarian that is only really possible with the freedom of

blade cutting.

With saw cutting the design has to be

drawn on to the veneer so that you have a guide line for the saw

blade to follow.

Scalpel cutting does allow the "spear

point" arrangement which is used for "blending" one veneer into

another. Saw cutting would rather preclude this method.

|

|

In this photo on the right you can see Silas using the

"parallel" saw on a veneer pack.

This saw uses the same clamp arrangement

that we saw Silas using with his hand held frame saw.

On the next page you will see some

examples of the veneer packs that Silas assembles for use with

this parallel cutting saw.

You will also see some of the completed

marquetry designs - and - especially for my own personal envy -

that wonderful old Leviathan of a press that Silas uses. It's a

superb piece of heavy engineering!

|

|

|

In the above you will have seen the main

differences demonstrated concerning the cutting techniques

required for dealing with the variations of veneer stock found

between the USA and the UK.

Those saw cutting techniques have the

inbuilt advantage of accurate packet cutting which guarantee you

a uniformity of repetitive pieces that it would be extremely

difficult to replicate with the scalpel method.

On the other hand, as we said earlier,

you do have the freedom to perform spontaneous cutting with the

scalpel blade that, in itself, would not really be possible with

the saw methods. As you see, both methods have their own

distinct advantages and disadvantages.

|

|

One further advantage with those thicker veneers is that you

will stand less chance when doing your "finishing" of

"rubbing through" your pictures' veneers into the base board

as often happens with our thinner veneers, and, oh! what an

awful sinking feeling that gives you when you see all your

hard work disappearing in a cloud of sanding dust!

The photo on the right shows a veneer pack assembled

together ready for the design to be placed on it and then

'cut out'.

Between some of the sheets of veneer a

few pages of waxed paper have been inserted in order to

lubricate the saw blade. It's much the same approach as we use

when we dip the tip of our cutting blade in a piece of wax to

lubricate the cutting point to avoid the "pulling" of the blade.

|

|

|

A series of "veneer packs" with the various parts of the

design placed upon them have been assembled ready for

cutting.

The packs have had "pilot" holes drilled

in them at strategic positions in order to facilitate the

insertion of the thin saw blade.

Each pack contains a different variety

of veneer which, when each cut piece is assembled, will supply a

specified amount of pre-cut items that will fit neatly and

uniformly into the main body of the work, thus ensuring a

continuity of design across the final project.

|

|

In this photo you will see that Silas is building up the

design of a Lilly using single sheets of the thicker USA

veneers together with an electric "piercing" type of saw.

Unfortunately with the saw method you

are rather prohibited from using the "window" method (which we

favour for our blade cutting techniques). Obviously, if you so

desired, you could make an attempt at the window method with the

saw, but I rather think that the saw blade would very easily cut

through your window veneer as well as your "insert" veneer

without "batting an eyelid" if you allowed it to!

|

|

|

Here you see Silas using the saw blade to cut an intricate

part of the design.

The blade follows the pencil line with

great accuracy. It also gives you the added advantage of being

able to cut through two adjoining parts of the design veneers at

the same time and thus ensure a perfect fit when you join the

veneers.

As you see here, the blades used for

these saw cutting techniques are almost like fine wires. They

are of a thinness that allows you to cut your veneers with great

accuracy.

|

|

The finished Lilly placed in it's well selected backing

veneer.

Although no blade cutting was used - or

no "window method" - you will note that the cutting is very

clean and the veneers have none the less, blended extremely

well.

I have come to the conclusion that there

is a lot to be said for the saw cutting methods used in the USA.

As you see here, they can produce some excellent results. I

think it would be nice to see what would happen if both methods

were used on one picture - that would be very interesting!

|

|

|

Well, we couldn't finish this piece without giving you a

view of Silas's press.

What a monster of a press this is!

How many of us marquetarians would love

to own such a superb item of machinery? I bet this couldn't half

produce some tonnage of pressure - and look at the bed size of

the beast - what dimensions of picture could you place in that I

wonder?

|

|

We hope you have found this article interesting. It highlights

an obvious difference in the marquetry techniques placed upon

the marquetarians who reside in different continents and is due

solely to the basic thickness of their veneer stocks.

As we said earlier on in this article, both cutting methods have

their own advantages and disadvantages - so, ultimately, the

choice of cutting is yours!

We would like to take this opportunity to thank Mr Silas Kopf

the owner of "Silas Kopf Woodworking" for his very kind

involvement in allowing us to publish these excerpts from his

DVD

"Silas Kopf Woodworking" manufactures bespoke furniture and

their web site is well worth a visit at:{

http://www.silaskopf.com }

I would thoroughly recommend Silas's "saw cutting methods" DVD

entitled "The Master Techniques of Marquetry" as an object

lesson in how saw cutting should be done.

There is only one small restriction for UK residents and that is

that the DVD is in the USA "NTSC" format and may not play

properly in some of the early DVD players - however, if you have

a computer with a DVD player in it, it should play perfectly in

that.

All the photos in this article are taken directly from the DVD

with no other intervention save for the gold frames, so you can

see how good the actual visual quality of the disk really is -

and the sound quality is also of that same high quality!

To order the DVD just visit the

{"SilasKopf"} web site as shown above for further details

|

|

Tutorials Menu

|