|

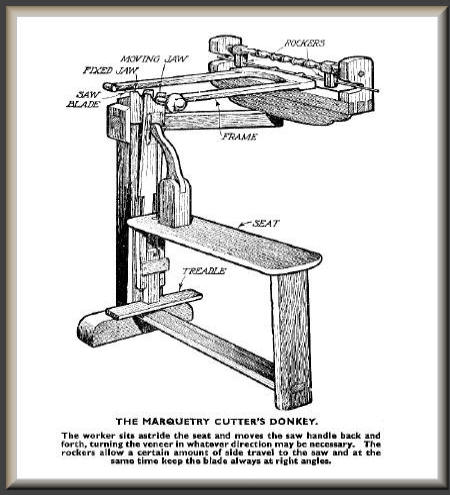

Marquetry Donkey Saw Adapted from a design by O. Bryan Morland first published in "The Marquetarian" issue 101 |

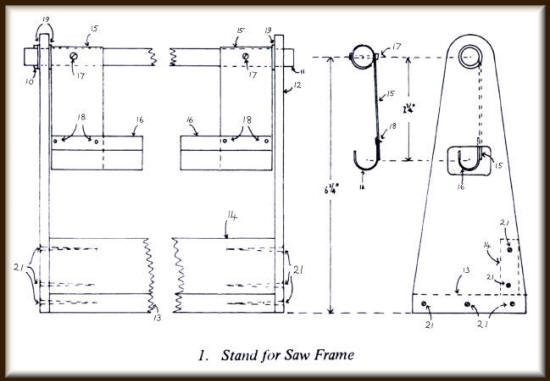

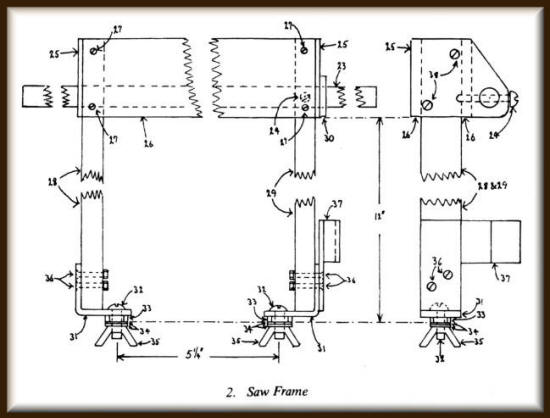

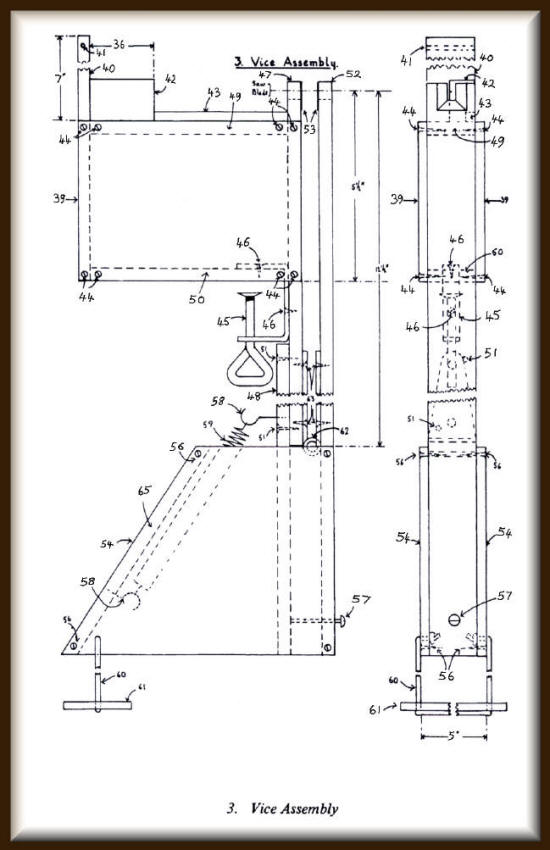

The component parts of the donkey saw |

O. Byron Morland using his donkey saw |

||

|

REQUIREMENTS FOR THE DONKEY SAW

|

|||

|

|||

|

|||

|

|||

|

The

illustrations above are copies of Mr O. Byron Morland's

drawings as originally published in "The Marquetarian"

magazine number 101 dated winter 1977.

Unfortunately in the original article there were no construction details published alongside the illustrations, but, we hope, that the illustrations along with the "parts list" as shown below should provide enough information to allow you to construct a donkey saw as seen in the 'top of the page' photos. If you have any problems in constructing the donkey saw and would like an answer to your problem, just send us an e-mail, using our "editorial team" address, and we will get our Alf Murtell to answer your question (Alf is our acknowledged authority on donkey saws). Below, we are including a copy of the original "parts list". (Don't worry that the list starts at number 11 because that is the way that the original list and article was written, and hopefully it all "came together" in the final 'sort out' and arrangement of the article!) Please note:

Where screws are listed

as C/Sk in the list below,

The abbreviation refers to "counter sunk" screws. |

|||

|

PARTS LIST

|

|||

|

FURTHER ITEMS NOT SHOWN ON DRAWINGS

|

|||

|

CONCLUSION The

first four of the "requirements" for the Donkey Saw as listed at

the top of this article have all been incorporated in the

design.

And the author further says: Whenever you bust the saw, remember it will be your own silly fault! ------------------------------------------------------------- Well,

we hope you found this article useful. It was based on the

design of an 18th century marquetry cutter's donkey saw.

------------------------------------------------------------- |

|||

LIne drawing of a variation of the Marquetry Donkey saw |

|||

| Tutorials Menu | |||